Kemppi 窄间隙焊接技术

Kemppi's Reduced Gap Technology (RGT) challenges conventional joint design principles

肯倍Master Tig氩弧焊机,肯倍Master手工焊机,肯倍Pulse铝焊机,肯倍A3机器人焊机,肯倍A7机器人焊机,肯倍KempArc机器人焊机,肯倍MIG焊机,肯倍X8 MIG焊机,肯倍不锈钢MIG焊机,肯倍MAG焊机, 西安肯倍焊机,武功肯倍焊机,渭南肯倍焊机,宝鸡肯倍焊机,汉中肯倍焊机,咸阳肯倍焊机,延安肯倍焊机,榆林肯倍焊机,鄠邑肯倍焊机,长安肯倍焊机。服务电话:15319752412,激光焊接 激光微加工 萃智激光研究院 。

Kemppi 的缩小间隙技术(RGT)挑战了传统的接头设计原则。

Reducing the groove angle can add significantly to efficiency and productivity of welding of heavy metal structures. Conventional narrow gap welding can be applied with most welding processes, but it has a disadvantage: it is practically impossible without equipment especially designed for the application. To overcome this constraint, Kemppi has developed a new solution, Reduced Gap Technology (RGT). This technology allows reliable and efficient narrow gap welding with no need for special equipment or accessories for material thicknesses of up to 30 mm. The solution combines intelligent arc control with Kemppi's high-tech power source, wire feeder and mechanization equipment.

减小坡口角度可显著提高重型金属结构焊接的效率和生产率。传统的窄间隙焊接可以应用于大多数焊接工艺,但它有一个缺点:没有专门为应用设计的设备几乎是不可能的。为了克服这一限制,Kemppi开发了一种新的解决方案,即缩小间隙技术(RGT)。这种技术允许可靠和有效的窄间隙焊接,不需要特殊设备或附件,材料厚度可达30 mm。该解决方案将智能电弧控制与Kemppi的高科技电源、送丝机和机械化设备相结合。

RGT changes our understanding of narrow gap welding

RGT改变了我们对窄间隙焊接的理解

In narrow gap welding, the groove angle is typically less than 20 degrees instead of the normal 45 to 60 degrees. This decreases the number of weld passes needed to complete the joint, and it reduces the welding time and the consumption of filler material. It also makes the material less prone to distortion. In other words, reducing the groove volume has a multitude of positive effects on welding quality, efficiency and productivity.

在窄间隙焊接中,坡口角度通常小于20度,而不是通常的45到60度。这减少了完成接头所需的焊道数量,减少了焊接时间和填充材料的消耗。它也使材料不易变形。换言之,减小坡口体积对焊接质量、效率和生产率有许多积极的影响。

However, reducing the groove angle also brings more challenges to welding. In a narrow groove, the welding arc is difficult to control. This may result in quality issues, unless you invest in welding torch and accessories that are specially designed for the application.

然而,减小坡口角度也给焊接带来了更多的挑战。在间隙坡口内,焊接电弧难以控制。这可能导致质量问题,除非您投资于专门为应用设计的焊枪和附件。

For narrow gap MIG/MAG applications with material thickness below 30 mm, Kemppi's Reduced Gap Technology (RGT) is an ideal new solution. It allows using standard welding equipment and welding application software for narrow gap welding of butt joints and fillet joints. The RGT solution combines the benefits of Wise application software, FastMig or X8 MIG Welder equipment, and A5 MIG Rail System 2500 welding mechanization system.

对于材料厚度低于30 mm的窄间隙MIG/MAG应用,Kemppi的缩小间隙技术(RGT)是一种理想的新解决方案。它允许使用标准焊接设备和焊接应用软件进行对接接头和角接接头的窄间隙焊接。RGT解决方案结合了WISE应用软件、FASTMIG或X8 MIG焊机设备和A5 MIG轨道系统2500焊接机械化系统的优点。

A control system ensures consistent power and precisely focused arc

控制系统确保稳定的功率和精确的聚焦电弧。

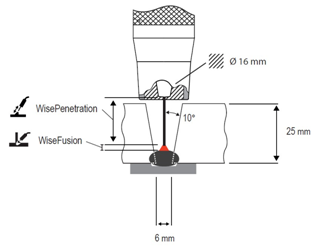

At the core of Kemppi's RGT solution is the most advanced arc control system available, which delivers consistent arc power at contact-tip-to-work distances of up to about 30 mm. In addition, the system adaptively adjusts the arc to keep its energy density at the maximum level (see Figure 1). A short, stable, and efficient arc minimizes the risk of incomplete penetration and lack of fusion, because the arc is always focused precisely at the desired point in the groove. The RGT control system enables reliable narrow gap welding of materials with thicknesses up to 30 mm, without the need for special equipment or accessories.

Kemppi的RGT解决方案的核心是最先进的电弧控制系统,使得导电嘴到工作最大距离接近30mm的情况下,依然能够提供了一致的电弧力量。此外,系统自适应调整电弧,使其能量密度保持在最大水平(见图1)。短、稳定和有效的电弧可将未焊透和未熔合的风险降至最低,因为电弧总是精确聚焦在坡口中所需的点上。RGT控制系统能够可靠地对厚度达30 mm的材料进行窄间隙焊接,无需特殊设备或附件。

肯倍Master Tig氩弧焊机,肯倍Master手工焊机,肯倍Pulse铝焊机,肯倍A3机器人焊机,肯倍A7机器人焊机,肯倍KempArc机器人焊机,肯倍MIG焊机,肯倍X8 MIG焊机,肯倍不锈钢MIG焊机,肯倍MAG焊机, 西安肯倍焊机,武功肯倍焊机,渭南肯倍焊机,宝鸡肯倍焊机,汉中肯倍焊机,咸阳肯倍焊机,延安肯倍焊机,榆林肯倍焊机,鄠邑肯倍焊机,长安肯倍焊机。

Figure 1. The principle of the RGT control system is that WisePenetration maintains consistent arc power regardless of variation in the contact-tip-to-work distance while WiseFusion provides adaptive regulation that keeps the arc focused and optimally short. In X8 MIG Welder, all of this functionality is combined in WisePenetration+ function.

图1.RGT控制系统的原理是,无论接触端到工作距离的变化如何,智能熔透都能保持一致的电弧功率,而智能熔透则提供自适应调节,以保持电弧的聚焦和最佳的短路。在X8 MIG焊机中,所有这些功能都结合在WISENTRATION+功能中。

Kemppi’s RGT narrow gap welding solution – for many direct benefits

Kemppi的RGT窄间隙焊接解决方案——有许多直接好处

Narrow gap welding provides many benefits, and in addition to those, Kemppi’s RGT solution offers many further advantages, for still greater cost savings and added value:

窄间隙焊接提供了许多好处,除此之外,Kemppi的RGT解决方案还提供了许多进一步的优势,以实现更大的成本节约和附加值:

•Investment costs are low, since no special equipment is needed in welding with material thicknesses under 30 mm.

•投资成本低,因为材料厚度小于30 mm的焊接不需要特殊设备。

•WiseFusion keeps the arc stable, improves the control of the weld pool and reduces the magnetic arc blow. This decreases the risk of incomplete penetration and lack of fusion, and it results in lower repair costs.

•WiseFusion可保持电弧稳定,改善焊接熔池的控制,减少电弧吹扫。这降低了未焊透和未熔合的风险,从而降低了维修成本。

肯倍MasterTig氩弧焊机,肯倍Master手工焊机,肯倍Pulse铝焊机,肯倍A3机器人焊机,肯倍A7机器人焊机,肯倍KempArc机器人焊机,肯倍MIG焊机,肯倍X8 MIG焊机,肯倍不锈钢MIG焊机,肯倍MAG焊机, 西安肯倍焊机,武功肯倍焊机,渭南肯倍焊机,宝鸡肯倍焊机,汉中肯倍焊机,咸阳肯倍焊机,延安肯倍焊机,榆林肯倍焊机,鄠邑肯倍焊机,长安肯倍焊机。

•WisePenetration keeps the arc power consistent, regardless of variations in the contact-tip- to-work distance. This enables a higher welding speed and deposition rate, and it results in lower labor costs.

•WisePenetration使电弧功率保持一致,无论接触端到工作距离的变化如何。这使得焊接速度和沉积速度更高,从而降低了人工成本。

•The high energy density of WiseFusion minimizes heat input, which improves impact toughness with high-strength steels and reduces deformation, so there is less need for straightening.

•WiseFusion的高能量密度使热输入最小化,从而提高了高强度钢的冲击韧性,减少了变形,因此对矫直的需求更少。

•WiseFusion keeps the arc length stable. The user doesn’t need to adjust it, for less hassle and a better arc time ratio.

•WISEFusion保持弧长稳定。用户不需要调整它,以减少麻烦和更好的弧时比。

Savings potential illustrated by a preliminary WPS

初步WPS说明节约的潜力

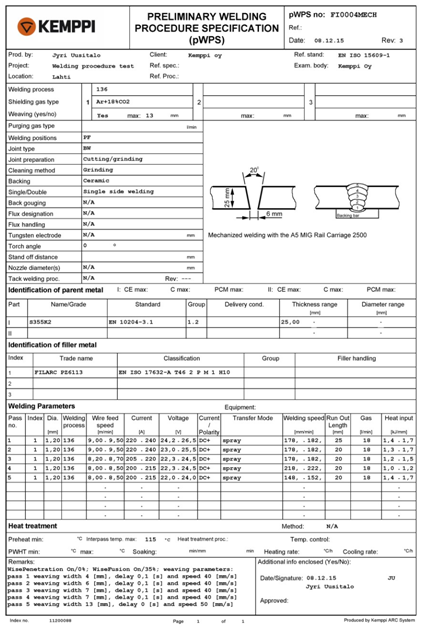

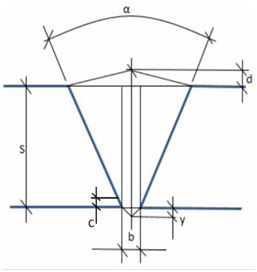

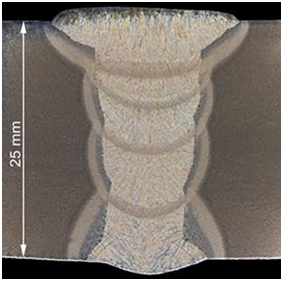

Kemppi’s RGT narrow gap welding solution has produced good results with a 20° groove angle and material thickness of up to 30 mm. The pWPS shown in Figure 2 is approved via tests in compliance with the standard on welding procedure qualification testing. It provides all the information required for the utilization of Kemppi's narrow gap solution in production welding. It was created for a butt joint with a 20° groove angle and a thickness of 25 mm. Figure 3 shows a calculation of the savings potential that the method yields. The smaller, 20° groove angle will result in a groove volume about 25% lower than with a 45° groove angle.

Kemppi的RGT窄间隙焊接解决方案在20°坡口和材料厚度高达30mm的情况下产生了良好的效果。图2所示的PWP通过符合焊接工艺评定试验标准的试验获得批准。它提供了在生产焊接中使用Kemppi窄间隙解决方案所需的所有信息。它是为具有20°坡口和25 mm厚度的对接接头而创建的。图3显示了该方法产生的节省潜力的计算。较小的20°坡口将导致槽体积比45°坡口小25%。

Figure 2. Preliminary Welding Procedure Specification (pWPS) for narrow gap welding of a butt joint.

|

图2.对接接头窄间隙焊接的初步焊接工艺规范(PWPS) |

Five weld passes |

|

Groove dimensions |

Current 45° groove |

New 20° groove |

|

Material thickness |

s = 25.0 mm |

s = 25.0 mm |

|

Bevel angle |

α/2 = 22.5° |

α/2 = 10° |

|

Root gap |

b = 4.0 mm |

b = 6.0 mm |

|

Root face |

c = 1.5 mm |

c = 0 mm |

|

Root reinforcement |

y = 2.0 mm |

y = 2.0 mm |

|

Reinforcement |

d = 2.0 mm |

d = 2.0 mm |

|

Groove volume |

A = 372 mm² |

A = 281 mm² |

|

Weight of weld metal |

G = 2.9 kg/m |

G = 2.2 kg/m |

Figure 3. Benefits of Kemppi's RGT narrow gap solution in terms of groove volume and filler material consumption. The 45° angle includes 1.5 mm root faces (c). The difference in the root gap is also considered (b). The 20° groove has sharp root edges.

图3.Kemppi的RGT窄间隙解决方案在槽体积和填充材料消耗方面的优势。45°角包括1.5 mm的根部面(C)。还考虑了根部间隙的差异(b)。20°槽有锋利的根部边缘。

Device and software requirements with the RGT solution

RGT解决方案的设备和软件需求

The narrow gap welding solution is available for Kemppi’s FastMig KMS, FastMig M, FastMig Pulse, FastMig X and X8 MIG Welder equipment. Use of this solution requires that the machine is equipped with the WisePenetration and WiseFusion application software. With X8 MIG Welder, only WisePenetration+ is needed, as it includes all necessary functions. The required Wise application software products are easy to purchase and install after machine purchase.

窄间隙焊接解决方案适用于Kemppi的FastMig KMS、FastMig M、FastMig Pulse、FastMig X和X8 MIG焊机设备。使用此解决方案需要机器配备WISE透和WISEFusion应用软件。对于X8 MIG焊机,只需要WISENTRATION+,因为它包括所有必要的功能。所需的WISE应用软件产品易于在机器购买后购买和安装。肯倍氩弧焊,肯倍手工焊,肯倍MIG焊

Arctech Helsinki Shipyard uses Kemppi's technology

赫尔辛基ARCTECH造船厂采用KEMPI的技术

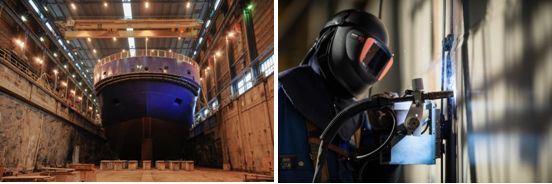

Among the users of Kemppi's RGT narrow gap welding solution is Arctech Helsinki Shipyard (see Figure 5), which has managed to reduce the groove angles from 45 to 30 degrees with the new technology. The shipyard uses WPS documents based on welding procedure qualification records (WPQRs) for mechanized welding in the construction of icebreakers. “Adoption of the new technology has brought us cost savings and improved the welding quality,” says Arctech’s Hull Production Manager Niko Rautiainen. “Welding work has gained speed, because the groove volume and the number of beads to be welded have decreased. Also less filler material is needed. Mechanization has also improved the arc time ratio and made the welds more consistent in quality,” he adds.

Kemppi的RGT窄间隙焊接解决方案的用户包括Arctech赫尔辛基造船厂(见图4),该造船厂利用新技术将槽角从45度减少到30度。在破冰船建造过程中,造船厂使用基于焊接工艺评定记录(WPQRS)的WPS文件进行机械化焊接。ARCTECH的船体生产经理Niko Rautiainen说:“采用新技术为我们节约了成本,提高了焊接质量。”“由于槽体积和待焊焊道数量减少,焊接工作加快了。也需要更少的填充材料。机械化还提高了电弧时间比,使焊接质量更加一致,”他补充说。

Figure 4. Welding of block sections of an icebreaker, using Kemppi's narrow gap welding solution, with Kemppi's A5 MIG Rail System 2500 and FastMig M 520 power source. Photos: Arctech Helsinki Shipyard.

图4.使用Kemppi的窄间隙焊接解决方案,使用Kemppi的A5 MIG轨道系统2500和Fastmig M 520电源焊接破冰船的分段。照片:赫尔辛基Arctech造船厂。 肯倍氩弧焊,肯倍手工焊,肯倍MIG焊

Summary

总结

The RGT narrow gap welding solution developed by Kemppi is based on an intelligent control system that keeps the arc power consistent regardless of the variations in the contact-tip-to- work distance. In addition, the system controls the arc adaptively, to keep its energy density at the maximum level. A short, stable, and efficient arc minimizes the risk of incomplete penetration and lack of fusion, because the arc is always focused precisely at the desired point in the groove. The control system enables reliable narrow gap welding of materials with thicknesses of up to 30 mm, with a 20° groove angle, from one side, and without the need for special equipment or accessories. Smaller groove volume yields significant cost savings through reductions in welding time and filler-material consumption. The method is excellently suited to both butt and fillet joints, no matter the welding position.

Kemppi开发的RGT窄间隙焊接解决方案基于一个智能控制系统,该系统可使电弧功率保持一致,而不管接触端到工作距离的变化。此外,系统对电弧进行自适应控制,使其能量密度保持在最大水平。短、稳定和有效的电弧可将未焊透和未熔合的风险降至最低,因为电弧总是精确聚焦在坡口中所需的点上。该控制系统能够可靠地从一侧以20°槽角、厚度不超过30 mm的材料进行窄间隙焊接,无需特殊设备或附件。通过减少焊接时间和填充材料消耗,较小的槽体积可显著节约成本。无论焊接位置如何,该方法都非常适用于对接接头和角接接头。

肯倍Master Tig氩弧焊机,肯倍Master手工焊机,肯倍Pulse铝焊机,肯倍A3机器人焊机,肯倍A7机器人焊机,肯倍KempArc机器人焊机,肯倍MIG焊机,肯倍X8 MIG焊机,肯倍不锈钢MIG焊机,肯倍MAG焊机, 西安肯倍焊机,武功肯倍焊机,渭南肯倍焊机,宝鸡肯倍焊机,汉中肯倍焊机,咸阳肯倍焊机,延安肯倍焊机,榆林肯倍焊机,鄠邑肯倍焊机,长安肯倍焊机。 服务电话:15319752412,激光焊接 激光微加工 萃智激光研究院 。